Parts and distribution traces should be sloped and fitted with drain points so that the program could be completely drained. In stainless-steel distribution units exactly where the water is circulated in a large temperature, useless legs and minimal-flow problems really should be avoided, and valved tie-in details must have duration-to-diameter ratios of six or less. If made of warmth tolerant plastic, this ratio needs to be even a lot less to avoid great points wherever biofilm growth could happen. In ambient temperature distribution devices, unique treatment really should be exercised to prevent or limit useless leg ratios of any sizing and supply for finish drainage.

Running Processes— Processes for functioning the water system and doing routine upkeep and corrective motion ought to be composed, and they also needs to outline the point when motion is needed. The procedures need to be properly documented, depth the perform of each job, assign who is accountable for undertaking the get the job done, and describe how The task should be to be executed. The usefulness of those strategies need to be assessed throughout water program validation. Checking System— Essential excellent characteristics and operating parameters needs to be documented and monitored. The program may possibly incorporate a mix of in-line sensors or automatic instruments (e.g., for TOC, conductivity, hardness, and chlorine), automatic or guide documentation of operational parameters (including movement fees or pressure drop throughout a carbon mattress, filter, or RO device), and laboratory exams (e.g., full microbial counts). The frequency of sampling, the need for assessing test results, along with the requirement for initiating corrective motion ought to be bundled. Sanitization— Based upon system structure and the chosen units of operation, regimen periodic sanitization may very well be required to preserve the method within a condition of microbial Command. Systems for sanitization are described over. Preventive Upkeep— A preventive routine maintenance application must be in result. This system really should create what preventive maintenance is to be executed, the frequency of routine maintenance do the job, and how the operate must be documented. Adjust Management— The mechanical configuration and operating disorders needs to be managed. Proposed modifications must be evaluated for his or her effect on the whole program. The need to requalify the procedure immediately after changes are made ought to be determined. Adhering to a decision to modify a water system, the affected drawings, manuals, and strategies should be revised. SAMPLING CONSIDERATIONS Water systems really should be monitored at a frequency that is ample to ensure that the method is in control and carries on to make water of suitable top quality.

For the duration of your inspection, figure out the supply of the water used for moist granulations or for just about any aqueous liquid preparations as well as for that laboratory. It ought to be of USP purified water quality each chemically and microbiologically.

Purified water: Purified water is used inside the preparation of all medication that contains water besides ampoules, injections, some Formal exterior preparations for example liniments.

MECO technologies are shaping the future of water purification. Our instruction and schooling aid presents your persons the information and self confidence to appreciate each of the productivity-enhancing possible we've designed into your MECO program.

Purified Water is used being an excipient/solvent within the production of non-parenteral preparations and in other pharmaceutical apps, such as cleansing of specified tools and non-parenteral merchandise-Make contact with components.

What follows is a short description of the assorted types of pharmaceutical waters and their significant makes use of or characteristics. Determine 1 may also be valuable in knowing several of the various types of waters.

When deciding which type of water method is necessary for pharmaceutical manufacturing it is important to keep in mind how the water are going to be applied to the merchandise. Water is used for concluded solutions or being an ingredient materials. Water which is used for completed goods, refers to packaging and labeling where There exists a minimal issue to the water used.

Purified Water— Purified Water (see USP monograph) is used being an excipient during the manufacture of nonparenteral preparations and in other pharmaceutical applications, which include cleansing of specific products and nonparenteral item-Make contact with components. Unless if not specified, Purified Water is also for being used for all tests and assays for which water is indicated (see Typical Notices and Demands). Purified Water is also referenced throughout the USP&#one hundred fifty;NF. Whatever the font and letter case used in its spelling, water complying Together with the Purified Water monograph is intended. Purified Water should meet the requirements for ionic and natural and organic chemical purity and need to be protected against microbial contamination. The minimum top quality of supply or feed water to the manufacture of Purified Water is Ingesting Water. This resource water could be purified making use of unit functions that include deionization, distillation, ion Trade, reverse osmosis, filtration, or other ideal purification treatments. Purified water methods have to be validated to reliably more info and continuously develop and distribute water of acceptable chemical and microbiological excellent. Purified water techniques that function beneath ambient problems are specifically susceptible to the institution of tenacious biofilms of microorganisms, which may be the supply of undesirable levels of practical microorganisms or endotoxins while in the effluent water.

Water for injection (WFI) is used being an excipient while in the production of parenteral as well as other preparations the place product endotoxin information should be controlled and in other pharmaceutical programs, for instance cleansing of selected tools of parenteral production.

Just like a water program manufacturing purified water, WFI methods also needs to be validated to reliably and continually make and distribute water of acceptable chemical and microbiological quality.

Pretreatment for water use: Biopharmaceutical businesses also use purified water as pretreatment in units in the preparing of WFI and pure steam manufacturing.

Cleaning laboratory equipment: Purified water is the greatest solution for washing method gear for non-parenteral product preparation and various product or service-Speak to containers. Purified water might also be used while in the Original washing of parts used in parenteral solution producing.

Water for Hemodialysis— Water for Hemodialysis (see USP monograph) is used for hemodialysis purposes, generally the dilution of hemodialysis focus answers. It really is generated and used on-website and it is created more info from EPA Drinking Water that has been even more purified to scale back chemical and microbiological components. It might be packaged and stored in unreactive containers that preclude bacterial entry. The phrase “unreactive containers” implies that the container, Particularly its water Make contact with surfaces, are usually not adjusted in almost any way by the water, for instance by leaching of container-associated compounds into the water or by any chemical response or corrosion caused from the water. The water has no additional antimicrobials and is not supposed for injection. Its attributes contain technical specs for Water conductivity, Overall organic and natural carbon (or oxidizable substances), Microbial boundaries, and Bacterial endotoxins. The water conductivity and overall natural and organic carbon attributes are identical to People established for Purified Water and Water for Injection; however, in lieu of total natural carbon, the organic and natural content may perhaps alternatively be measured from the examination for Oxidizable substances. The Microbial boundaries attribute for this water is unique among the “bulk” water monographs, but is justified on the basis of this water's particular application that has microbial material demands relevant to its Harmless use. The Bacterial endotoxins attribute is Furthermore recognized in a amount connected to its Harmless use. Pure Steam— Pure Steam (see USP monograph) is usually in some cases generally known as “clean steam”.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Barbi Benton Then & Now!

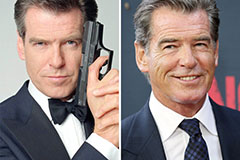

Barbi Benton Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!